Leacraithnaich Bothy, Lochaline, Morvern: A new lease of life for an old friend.

A report on the renovation of the bothy, April-May, 2019

The Leacraithnaich Bothy project has taken approximately two years to complete from the first indication that there was a real issue with the building’s roof and that we needed to do something about it, through the planning stage, the construction on site, the completion of all work, and on to making this renovated project available for public use.

Site works commenced on Saturday, 27 April and concluded on Sunday, 26 May 2019. Four of us went in ahead on Thursday, 25 April in order to get things rolling. Spring 2019 has been the driest in recent memory for Ardtornish and its hydro generation has all-but dried up. It’s something the estate was not happy about but we were delighted! The large number of good days with dry weather made the construction phase that bit easier.

The materials for the build were dropped off at the estate stores by the suppliers, and the Ardtornish staff helped us enormously by transporting the bulk of the large and heavy items to within 500m of the bothy, including one-tonne bags of sand and gravel mix, something that would have taken a lot of time and energy for us to do ourselves. We also had the loan of the estate’s cuplok scaffolding that was delivered to us for use.

Our first task was to build the temporary accommodation – a wood frame and plastic sheeting canteen (that doubled as a social area in the evenings) had an adjoining storage area for equipment. This tool shed was a great help (we had a large supply of tools and machinery) but it was not long before tools were scattered all over the place and made a nightly tidy-up vital.

THE PEOPLE:

Our volunteers

Almost 100 people showed an interest in attending this project during the months prior to start, but only approximately 56 commitment to attend – a blessing, in fact. Very few were no-shows, and of those, most communicated that they would no longer be able to participate. The task of managing these numbers into a resource that matched our expected workload at any one time was not straightforward. With hindsight, the shifts mostly worked out OK and only once (a weekend) did we reach a peak of 17 volunteers on site. Thankfully we had a lot to do and a large lime-pointing squad was set to work.

Our volunteers made this project. We were so reliant on them and the various hard and soft skills they brought with them to Leacraithnaich. They were willing, enthusiastic and hard-working, keen to step up to new challenges as well as hone an established skill. Without their effort, this project would not have happened. I thank them very much for turning up, doing the job and engaging in good craic along the way.

Outside the build, we made time for a table tennis tournament, flew a kite, had a swim in the Loch, went for walks and tried to catch a fish. During the third week, Fiona and Ian Johnston joined us. Fiona brought along her accordion so a ceilidh in the part-finished bothy was in order. We sang familiar songs, learned a new song in gaelic that took some remembering, and then some solos were heard. A ghost story rounded out the evening’s entertainment. I like to believe we may have awoken the bothy from its slumbers for a new lease of life.

I hope all volunteers take away with them an appreciation of the MBA values in addition to their new skills. You can be proud of the way you have supported this worthwhile project. Do come back in the next few years and see how this bothy has been absorbed back into the landscape.

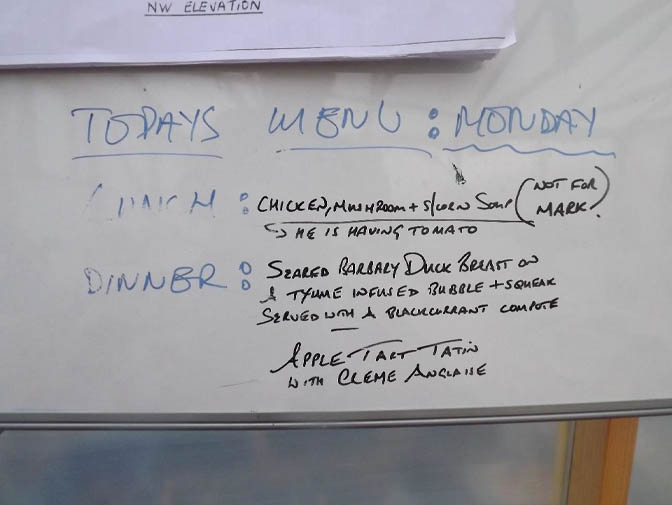

Our cooks

We were ably supported by two cooks during our month on site. Alex MacLeod worked for one week before handing over to John Arnott who continued to the end of the build. Cooking for a large group is a difficult task to perform in a remote place without mains electricity nor water on tap. The number of volunteers fluctuated each day, and frequently within the same day. The water in the local burn dried up this spring and our water was carried in x3 50L containers (we used up to 150 litres a day) from 1km away. We enjoyed fresh-baked bread, minestrone (with creative combinations of added ingredients), curry, chilli, gravy, sausages, bacon rolls and soup most days for lunch. All our meals were excellent. A big thank-you goes out to Alex and John from each of us.

The organising team

A special thankyou goes to Jim Ross who produced the designs, progressed the Building Control issues, liaised with the suppliers and personally constructed much of the off-site build. Without this help the project would not be where it is today. Also, Allan Young, who as MO for the bothy acted as liaison with the estate for the many issues that arose.

THE SITE:

The canteen

Our canteen was built as a 4.8m base with full-length work surfaces on two sides for the cooks’ use. We installed a sink in one of the sides and a microwave cooker was available on the other when needed. Photovoltaic (PV) lighting was provided over the work area if needed.

The dining table was a 1.2m x 2.4m OS board, loosely resting on the existing bothy table. Seating 17 people around it was a challenge, however the lesser numbers that were the norm could be accommodated more easily. A separate drinks table was a must on a project like this!

THE BOTHY:

Removal of the roof

Existing drive nails were more deeply embedded than anticipated and attempts to remove them using a wrecking bar and hammer proved an impossible task. An angle grinder was eventually used to cut off the heads. This process proved quicker, but there were a vast number of nail heads still to remove. Once these were gone, the old corrugated sheets could be taken down and handed to ground level for transportation to the estate skip where they were to be recycled. On roofreplacement projects, these sheets often hang around at the back of a bothy for a year or two, even more. But on this occasion the process of disposal was made quick and easy.

After much deliberation about how best to remove the existing 6 large roof trusses, a method statement was produced. Once they could be seen clearly, we changed our method again and did something different! I must add that the final removal method worked well – it remained safe and no damage to the wall heads occurred.

Craig Marshall, the recently appointed Health and Safety adviser to the MBA, attended the project and noticed no defects during his visit. He provided some useful feedback that will be built into future projects.

Renovation of the wall heads

Once the roof was off, the full extent of the work needed to renovate the wall heads on both sides and ends of the bothy was revealed. The wall heads at the gable ends needed a lot of work and this took more time than anticipated, however with the help of 17 volunteers, we had enough people to complete the job.

Installation of the trusses and roof sheets

Installation of the trusses and roof sheets

After careful measurement, the first trusses were quickly installed. Corrugated aluminium roof sheets were next (pre-measured to fit this roof so that a single sheet ran vertically from top to bottom) were held down by 8mm stainless steel screws.

Two Velux windows were installed in the rear to allow light into the bothy via clear ceiling sheets above two of the rooms.

Flashing was installed on the chimneys and aluminium gutters and down pipes were added to the front and rear of the building.

Lime pointing

A considerable amount of lime pointing was undertaken on both internal and external walls. The exterior of the western and southern elevations needed the most work as these faced the prevailing winds and rain and the old mortar was falling out. The other two external walls needed much less work. More than one tonne of sharp sand was used in the pointing process and a number of volunteers were kept busy over many days. For some, this was the first time they had carried out pointing work, but there were also many veterans of this process.

The intense sun and dry wind did not help in curing the mortar, so frequent misting was required to keep the mortar from drying out, we hung hessian sack to shade the external walls.

Internal fittings

We updated the bothy’s interior layout to accommodate three rooms (two with a fireplace), one with a sleeping platform plus an internal porch.

Tongue and groove boards were used for the ceiling and for cladding all stud walls inside the bothy. Once the measurement process had been established, the system became efficient and kept six volunteers busy for several days. The existing internal stone walls were pointed, so we did not apply cladding to them.

Insulation was rolled out above the ceiling in the roof in order to retain heat.

FINAL STAGES & COMPLETION:

Building Control

During the third week we were inspected by Building Control from Fort William. The inspector arrived by bike on a stinking hot day and looked like he was about to expire, so we gave him cold drinks and Christmas cake to revive him. He reviewed the build and compared what we had done with the drawings, reporting that all was well.

In the near future, and when the works are completed, a final check will be required before a warrant is issued.

So, is the work finished?

We nearly completed the bothy, however the fire-retardant varnish layer gave us problems. The safety data sheet did not adequately reflect the severity of the eye and respiratory irritations likely to occur and we had to stop the job. No large fans for hire were available in Fort William and we have delayed the work until we can determine a safe process. We hope to complete the job during the next couple of months.

Otherwise the bothy is complete and we are rightfully proud of our work. Well done to all the volunteers.

New ideas tested

1. The shower.

This was a great success. We built a gas water heater into a prefabricated cubicle and it worked well from the start. The boiler was bought in Czechia, the only place where a model that suited our requirements was available. We needed a boiler that allowed a wide tolerance of input water pressures and still function as expected. Our calculations indicated that we needed a 10m vertical height to attain the correct pressure levels and remain within the tolerance of the boiler’s operating envelope. We used a garden water tub and connected it with a 20mm pipe, locating it on a reliable burn that thankfully still continued to flow during the drought. The system only failed to work on three mornings when overnight frost froze the water pipe, and on one of these nights we had 10-inch icicles on the inlet to the water tub. Yes, this was May. The boiler recovered each time from the temporary freeze.

2. The fridge-freezer.

A 230v power socket was available to us at a distance from the bothy, so we decided to use a fridge/freezer. We acquired one free in Fort William, but its donor lived on the third floor. Well done to Mark Fitton and Jim Ross who struggled down three flights of stairs and transported our refrigeration to site. Access to a fridge gave us a better selection of meals and we did not have to rely so much on canned food. The weather was very hot at times and the fridge was essential to keep our food supplies fresh.

3. The toilet.

A prefabricated toilet was constructed with a removable 50-litre sealable barrel as the waste container. This made the process of transporting the load from site to the Estate’s septic tank much easier and hygienic.

4. The canteen sink.

A brand-new sink and drainer was acquired for £10 via Gumtree and built into another prefabricated unit, this new setup making the cooks’ job that bit easier. An outlet pipe vented into a hole that was dug just outside the temporary canteen meant the eco-friendly effluence should not be a problem for the future.

5. Power supply.

A PV power supply in the canteen provided LED lighting and two points for charging mobile phones. The volunteers preferred candlelight in the evening, but the LED lights helped at times. It may not be a vital requirement for next time.

6. Reuse of temporary units.

All of the temporary units (canteen and tool shed, sink unit, WC, shower) will be stored for reuse on similar projects in future.

THE ESTATE:

Working with the Ardtornish Estate

Assistance from the estate team was considerable and enthusiastic. Materials were received and stored for us and delivered by tractor and trailer to within 500m of the bothy. Some of the scaffolding was also moved for us to the bothy by Argo cat.

We were provided with two storage areas for materials, one long-term storage facility and an open barn area where we could work under cover and paint items under cover.

We used the estate’s recycling point for glass, tins, plastic and paper. Also their septic tank for the toilet waste.

The construction materials for this project were paid for by the estate at a cost of £12k, not an inconsiderable amount. We thank the Ardtornish Estate for their commitment to this project and for the funding of the materials.

MISCELLANY:

A few facts and figures from the project you may find interesting

Wildlife and nature

Golden eagles and white-tailed sea eagles, diving birds on the Loch, one swan and possibly a slow worm were seen from the bothy. Snipe drummed at night, the drumming of their tail feathers audible from the comfort of a sleeping bag. No wildcats were seen as they are so rare but that is not surprising. We were woken to the sound of cuckoos in the mornings and deer walked around our tents at night, eating the grass. Ticks were easily picked up, especially if you went off-piste into the long grass. The tick removers from the first aid kit worked well. We made tracks around and through the prolific bluebells in the areas between our tents.

GOING FORWARD:

Lessons learned and follow-up actions

1. Heavy-duty drill.

We need a heavy-duty drill available for future projects like this so we don’t have to hire one. Cost is a factor, but mainly the time spent collecting and returning the items like these can stall work. More than half a day and an 80-mile round trip that included two ferry crossing was required on this occasion.

2. Delivery of materials.

Check all materials delivered to site are as expected, and still there when needed.

3. Supplier Contact Details:

Have telephone numbers of local suppliers available for when you need them, because you will!

4. MBA credit card.

The MBA card receipt process needs reviewing for long-term projects such as this one.

5. Petty Cash.

There needs to be a way to provide volunteers with up-front financial loans for significant items to be purchased, especially food. Incidental costs of up to £500 per week can be expected on a project with this number of volunteers.

6. Safe use of tools.

Need to minimise the risk of hand-arm vibration when using angle grinders over a long period of time. Detail the control measures in the risk assessment.

7. Safe use of scaffold.

Need to investigate fall restraint systems for volunteers working on scaffold systems when undertaking wall head renovation.

8. Volunteer Emergency Contacts.

Provide better information for families of volunteers for emergency contact.

9. Rest.

Programme time to enjoy your hard work before you hurry off site and back to your normal life.

CONCLUSION:

We left the bothy on Sunday, 26 May after 32 days of continuous work party activity. The dry weather allowed us to achieve our programme of work and to deliver on time. Many interesting conversations were held around the canteen table and long-lasting friendships were started. The support of 54 volunteers from all walks of life and levels of skill was vital in achieving the desired end result; it was a joy to have them along. We thank them very much for giving so much of their time in willing support of this worthwhile cause, and we look forward to seeing them again on another day and in another bothy.

Produced by Peter Rowell, Edited by Rebecca Strong.

Area Organiser, South West Highlands and Islands, for the Mountain Bothies Association.

The MBA is a charity registered in Scotland SC008685 and a company limited by guarantee, registered in Scotland SC191425.

“To maintain simple shelters in remote country for all who love wild and lonely places”.

www.mountainbothies.org.uk

Registered Office: MBA, Henderson Black & Co, Edenbank House, 22 Crossgate, Cupar, KY15 5HW